Smart Manufacturing

Struggling to keep up with increasing customer demands, rising energy costs, or skills shortages?

Smart manufacturing isn’t just for big factories – it’s the key to boosting productivity, agility, and competitiveness for manufacturers of all sizes.

Digital Technologies in Manufacturing

We help manufacturers adopt and implement Digital Technologies to support productivity and automation.

BrookConsult’s team of specialist Digital Manufacturing consultants work with your business to help you identify and embed digital technology into your processes to enhance efficiencies, procedures and quality.

We will work with you to develop your technical specificiation and provide detailed implementation planning, including risk analysis & mitigation, to ensure your investment in your technology selection and approach is the best solution.

Say goodbye to unexpected downtime. With AI-driven predictive maintenance, manufacturers can cut unplanned failures by as much as 70% and reduce maintenance costs by 25%.

Project Management Support for Digital Systems Implementation

Implementing digital systems such as Enterprise Resource Planning (ERP), Manufacturing Resource Planning (MRP), Production Planning, or Customer Relationship Management (CRM) software can be transformative for your business, but without the right project management, these initiatives often fail to deliver their promised benefits.

At BrookConsult, we specialise in providing professional project management support for digital transformation projects. Our experienced project managers help manufacturers and engineering businesses achieve successful implementation of ERP, MRP, production planning, and CRM systems, ensuring your investment delivers measurable improvements in efficiency, quality, and profitability.

Our project management support includes:

Requirements capture and business analysis

Defining your business processes and aligning them to the capabilities of your chosen system.

Scope and project planning

Developing clear objectives, milestones, budgets, and timelines.

Stakeholder engagement and communication

Ensuring buy-in from leadership, employees, and system suppliers.

Risk assessment and change management

Proactively managing challenges that could impact your project.

Supplier coordination

Liaising with software vendors, system integrators, and third-party consultants.

Data migration planning

Developing robust plans to move and validate data.

User acceptance testing (UAT)

Managing testing phases to ensure the system meets your operational needs.

Go-live support and stabilisation

Providing on-the-ground support to resolve issues quickly and ensure a smooth transition.

Post-implementation review

Capturing lessons learned and continuous improvement opportunities.

Whether you are upgrading an existing ERP system, implementing a new MRP solution, rolling out a CRM for the first time, or deploying advanced production planning tools, our project management services provide the structure, expertise, and oversight you need for success.

By partnering with BrookConsult, you gain more than just project oversight, you gain a trusted advisor who understands the complexities of manufacturing and engineering environments.

We bridge the gap between technology and business goals, ensuring your systems not only go live on time and on budget but also drive long-term value and growth.

Our focus is on building lasting capability within your teams, so the benefits of your digital transformation extend well beyond the initial implementation.

Where Outsourced PMOs Add Value in Manufacturing

An outsourced Project Management Office (PMO) can be a game-changer for manufacturers, providing specialist skills, proven methodologies, and the flexibility to scale resources up or down without adding permanent headcount. Whether driving operational excellence, managing multi-site programmes, or delivering complex capital investments, an external PMO brings focus, pace, and consistency.

Manufacturing Operations Improvement

- Overseeing Lean, Six Sigma, and other continuous improvement initiatives.

- Managing operational efficiency and cost-reduction programmes.

- Coordinating Kaizen events, 5S, SMED, and other performance-boosting rollouts across sites.

Digital Transformation & Industry 4.0

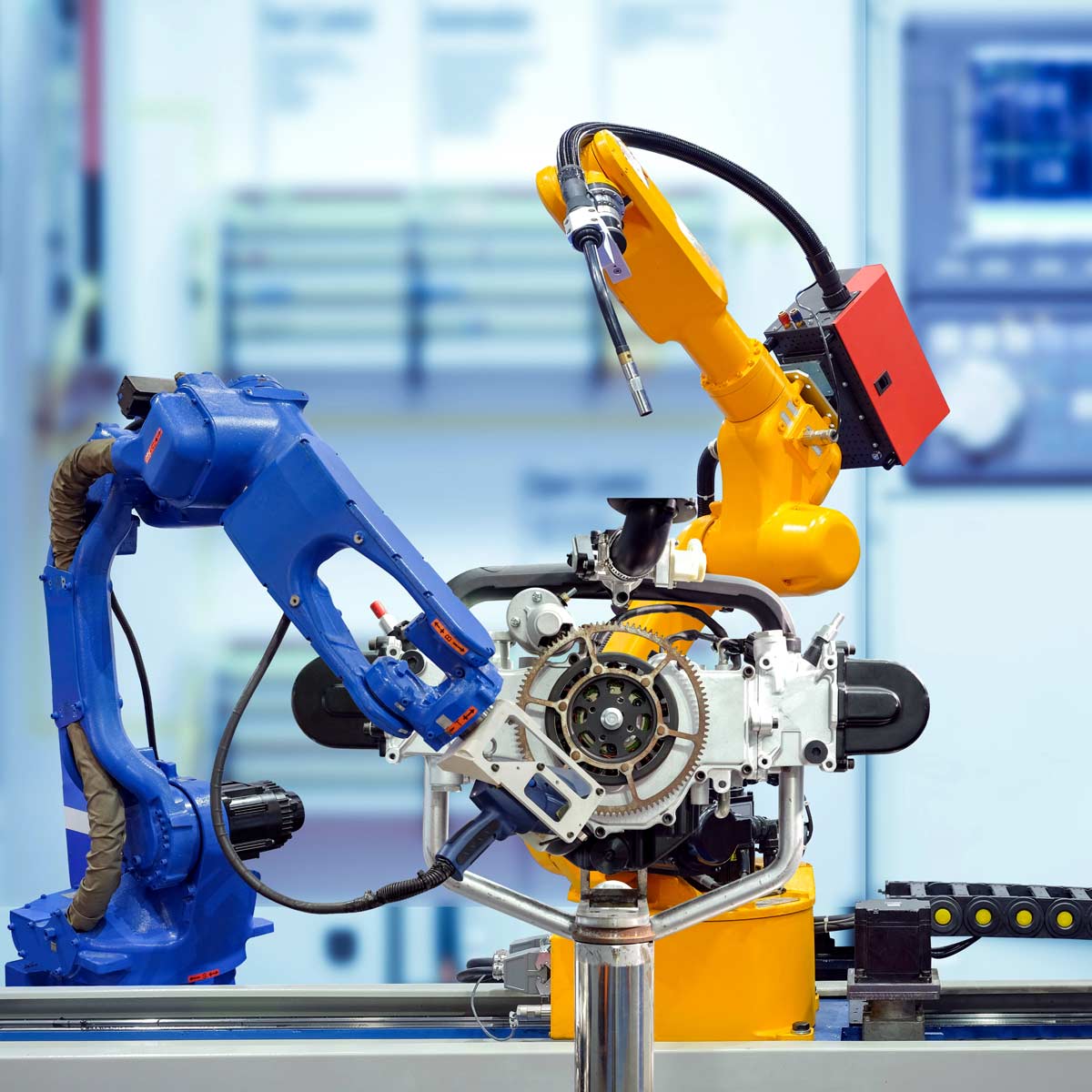

- Leading smart factory and digitalisation projects such as MES, IoT, AI, and robotics.

- Managing digital roadmaps, vendor engagement, and technology pilots.

- Supporting diagnostics (e.g. SIRI, EDGE) and capability-building programmes to prepare teams for change.

Capex & Engineering Projects

- Delivering large-scale investments like new production lines, factory builds, and equipment upgrades.

- Controlling schedules, budgets, stakeholder communication, and risk.

- Overseeing construction, commissioning, and seamless handover to operations.

Supply Chain Projects

- Coordinating supplier onboarding, outsourcing, or re-shoring strategies.

- Driving procurement transformation or ERP system rollouts.

- Managing logistics optimisation and warehouse automation projects.

Quality & Compliance

- Leading ISO certification or audit preparation (ISO 9001, IATF 16949, ISO 14001).

- Overseeing CAPA, PPAP, APQP, and FMEA process improvements.

- Ensuring regulatory compliance in demanding sectors like automotive or medical.

Why It Works

Outsourcing your PMO gives you a delivery partner who can slot seamlessly into your organisation, act with independence, and keep every project on track. You get robust governance, faster problem-solving, and an experienced team that speaks the language of manufacturing. Most importantly, you gain the confidence that strategic projects, whether operational, digital, capital, or compliance-driven, will be delivered on time, on budget, and to the highest standard.

Get in touch today to discover how our project management support for ERP, MRP, production planning, and CRM systems can help your business thrive.

Frequently Asked Questions

Smart Manufacturing

Industry 4.0 is about using data, automation and digital tools to improve decision-making, efficiency and competitiveness. It focuses on solving real business problems rather than investing in technology for its own sake.

Readiness depends on leadership alignment, process maturity and workforce capability, not just existing technology. A structured assessment helps identify gaps and prioritise the right improvements.

We begin with clearly defined business challenges rather than jumping straight to solutions. This ensures technology investments are targeted, practical and deliver measurable value.

No. Digital transformation can be scaled to suit businesses of all sizes. SMEs often benefit significantly when improvements are aligned with clear operational goals.

Well-targeted digital improvement projects often show measurable returns within months rather than years, particularly when focused on efficiency, data visibility and waste reduction.

Smart Manufacturing

Smart Manufacturing Struggling to keep up with increasing customer demands, rising energy costs, or skills shortages? Smart manufacturing isn’t just for big factories – it’s